Green Engineering: Cutting Energy Consumption in the Tropics

Create a Holistic Model; Monitor and Manage Inputs and Outputs in Real Time; Provide Visualization Tools

What are the current best practices in green engineering? Travel with us to Malaysia to learn how to cut energy costs by 60% when cooling buildings in the tropics. Today’s green engineers use low-cost, distributed sensors to provide real-time data feeds about real-world events. They use this data to build and refresh models of complex systems. They trigger actions based on events and thresholds. They provide visualization tools to see what’s going on in complex systems. They monitor the patterns of behavior in each system and across systems to detect changes over time. Their systems adapt to new conditions and behaviors. These same approaches serve us well as we design customer-adaptive solutions.

NETTING IT OUT

In this series of “green engineering” papers, we look at ways in which scientists and engineers are creating models of complex systems, in-formed by the use of distributed sensors, to de-tect, monitor, and control inputs and outputs.

They develop algorithms to describe the interrelationships they see taking place. The models they build are informed by the real-world phenomena that take place. These models “learn” and adapt as they become more and more intelligent. A key ingredient is visualization software the lets users visualize what is actually occurring in the physical world.

We see a lot of correlations between green engineering techniques and trends in customer-adaptive design of products, services, and businesses.

For example, in order to be truly customer-adaptive, your products and services should be instrumented in such a way that you can tell how customers are using them and what they are doing. We often refer to this as “building intelligent systems.” Systems become intelligent because they have sensors (physical, electronic and/or software) built into them to record and report activity.

Ideally, you want to use this real-time data to build a model of how your products and services are being used. Then you can identify new patterns of usage, see when customers are trying to do new things, and run around in front of the parade to add those capabilities to your solutions.

You want to be able to visualize the complex interrelationships of customers’ actions and their success rates as well as the impact that has on your bottom line.

Whether you are designing a customer dashboard to monitor how you’re doing on customer experience or a piece of equipment that’s used in manufacturing, healthcare, or food processing, your next-gen solutions should be using these now cost-effective sensing, modeling, controlling, and visualization techniques that are being used in green engineering to create environmentally-friendly solutions.

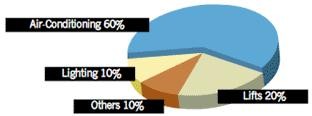

Where Can You Save Energy in Commercial Buildings?

© CEMS Engineering

In tropical countries, energy consumption for air conditioning accounts for 60 percent of total building energy costs.

MODELING & CONTROLLING THE REAL WORLD USING SENSORS, FEEDBACK & VISUALIZATION

“Thiru” (Thirumalaichelvam Subramaniam) is the Chief Technical Officer of CEMS Engineering in Malaysia. Thiru has been pursuing his dream of energy conservation for the facilities he manages for two decades. Within the last three years, he has developed a breakthrough approach for improving the quality and energy efficiency of commercial air conditioning systems (office buildings, factories, hospitals) in the tropics. He has saved his clients up to 30 percent of their air conditioning energy costs in tropical countries in which cooling costs typically consume 45 to 60 percent of buildings’ energy expenses.

The key to the success of Thiru’s approach is real-time data acquisition, dynamic analysis of outside air parameters and chilled water, and real-time synchronization of multiple air conditioning components into one comprehensive thermal system. In addition, his team’s Chiller Energy Management System (CEMS) is operated remotely via the Internet. This lets CEMS energy experts optimize their clients’ facilities’ energy conservation, while lowering clients’ equipment costs and prolonging equipment life through usage-based predictive maintenance. After two years of development and testing, CEMS has been successfully deployed in a dozen facilities in Malaysia and Singapore. That’s only one percent of the potential market in those countries. There is also a growing demand for this type of system in more than 700 plants and office buildings in India, Philippines, & Thailand.

A Career-Long Fascination with Energy Conservation and Holistic Modeling

Thiru Subramaniam, a third-generation Malaysian, studied engineering in the U.K. “I started out in aircraft maintenance in Malaysia, but quickly became bored with maintenance, so I took my advanced degree in mechanical engineering in the U.S. in the 80’s and began to specialize in the design and operation of process manufacturing plants.”

Thiru’s Quest: How to Make an Entire Manufacturing Plant Energy-Efficient?

“What I noticed at the time,” Thiru explained, “was that everyone specialized in particular manufacturing processes, but nobody seemed to be focusing on the efficiency of the whole plant—particularly in its use of energy. This really hit me when I returned to Malaysia and began to work in process manufacturing. In 1989, I was involved in the design and operation of a calcium carbonate processing plant. It was the first of these plants in the world using roller mill technology, and there was no manual or documentation that I could use to optimize its operation.”

Needed: A Holistic Model of End-to-End Operations. “I realized that I needed to build a model of how the entire plant operated end-to-end. I quickly realized that it was not going to be a feasible plant to run economically. The energy costs were much too high, even in Malaysia, where energy costs were largely subsidized by the government at the time.”

In order to build a model of the plant’s operations, Thiru used ...

Sign in to download the full article

0 comments

Be the first one to comment.